Hydrogen Technology

Making use of new energy conversion concepts including renewable energy resources became a significant topic in research and development for available, reliable, safe and affordable CO2-reduced or Carbon-free technologies for satisfying todays and tomorrows demand for energy supply of the industrial users as well as of the private users. “Hydrogen” became an emerging topic in these concepts. For example, in order to store the excess power of the renewable energy resources, various “Power to X” concepts are developed, in which Hydrogen takes an important role as energy carrier and storage medium.

Due to the strong collaboration of our company B&B-AGEMA with partners from Universities and Industry, we are heavily involved in the research and development of these technologies. Beside as working as engineering service provider in research and development tasks, we are actively developing solutions with our partners for Hydrogen integration into the power generation processes. We are dealing with the aspects of Hydrogen generation, transportation, utilization and infrastructure.

Combustor Technology

B&B-AGEMA has experienced design engineers for the comprehensive design and testing of gas turbine combustors. The scope of design includes all kind of thermomechanical aspects for complete conception of can-type combustors for stationary gas turbines.

With regard to combustion of fuel with very high content of Hydrogen and, in particular, for pure Hydrogen, Kawasaki Heavy Industries, the Institute of Steam and Gas Turbines (IDG) and B&B-AGEMA signed a long-term general agreement in 2010 for the development of a low-emission Hydrogen combustion technology for gas turbines. Within this collaborative agreement B&B-AGEMA developed together with Kawasaki the innovative "MicroMix Combustor Technology" for real gas turbine applications. The technology is derived from fundamental research on the Micromix Flames performed at the University of Applied Sciences Aachen. B&B-AGEMA transferred the atmospheric low-energy Micromix flame results obtained at the University of Applied Sciences Aachen by application of modern combustion simulation techniques to the high pressure and high energy conditions in a gas turbine.

Based on the collaborative work of the partners within this long-term development, successful operation of a prototype combustor for a 2 MW gas turbine at 100% load conditions as well as for engine start-up conditions has been accomplished at test facilities in Akashi, Japan, and Aachen, Germany. The high-pressure combustor test facility established by the IDG is unique in its design and essential for the testing of combustors under real (1:1) gas turbine conditions. Finally the world-wide first 100% Hydrogen-fueled gas turbine with the developed MMX combustor is in successful operation in Kobe, Japan, since July 2020. Kawasaki’s “Hydrogen Road”

For further information on combustor design for “Micro Mix Combustion” technology, we like to refer to the webinar with Siemens PLM about Predicting performance and improving combustor design: how B&B-AGEMA uses simulation for digital testing (this video is directly available after registration). Additional material can be found in our list of publications.

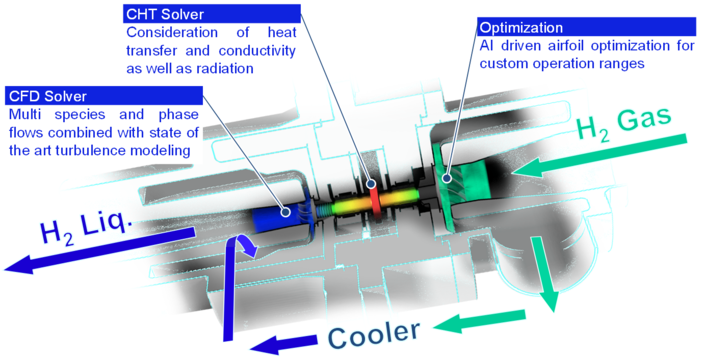

Turbo Component Technology

The future hydrogen world offers a new variety of applications, process cycles and challenges for essential devices like turbo pumps, compressors and liquefier. A sustainable hydrogen infrastructure needs reliable turbo components to safely store and transport the hydrogen. A core competence of B&B-AGEMA is the aero thermal design of these important devices. We excel in providing designs from the scratch as well as upgrades. With our AI driven design approach we are able to support our clients with custom and efficient solutions.

Innovative Thermodynamic Cycle Technology

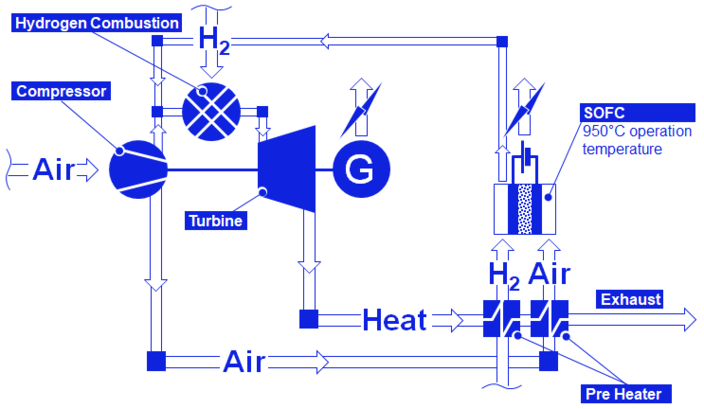

Since the 1990s B&B-AGEMA worked on research projects with the Institute of Steam and Gas Turbines (IDG) of RWTH Aachen University for innovative gas turbine cycles, in order to boost the efficiency of power generation. In 2002, IDG and B&B-AGEMA introduced their innovative micro gas turbine cycle combined with a high temperature fuel cells system.

This cycle obtains highest efficiency for small-scale and decentralized power generation, by coupling a solid oxide fuel cell (SOFC) and a so-called micro gas turbine in one power generation system and making advantageous use of the heat generated by its core components. Further, this cycle offers capabilities for use of Hydrogen locally generated in a decentralized system for power supply as well as Hydrogen grid applications.

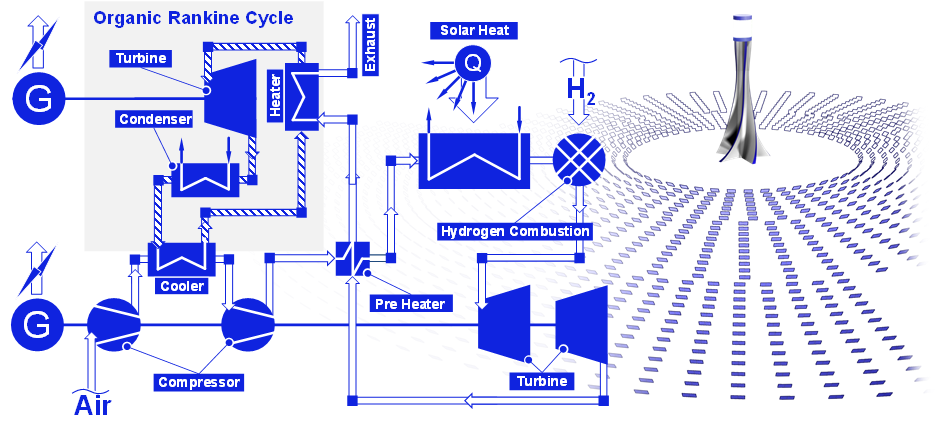

High efficient solutions for Carbon-free power generations by combining a solar hybrid gas turbine cycle with an Organic Rankine Cycle (ORC) have been developed together with industrial partners, e.g. Kawasaki Heavy Industries, Ltd.. Basically, such cycle can provide consistent electrical power due its hybrid technology making use of solar power as well as Hydrogen fuel. For additional increase in efficiency, the implemented ORC utilizes the heat transferred from the gas turbine cycle at different locations. Due to the lower temperature regime and for compactness of the system special Organic fluids are chosen as operational fluids of the cycle.

These technologies have been developed by application of B&B-AGEMA software products as Thermodynamic Design Tool (TDT), Axial Compressor Flow 2D (ACF2D), Axial Turbine Flow (ATF) and Gas Turbine Performance Simulation (GTP-Sim). Furthermore, all these tools can be coupled with Simcenter STAR-CCM+ & HEEDS in order to optimize component dimensions and operational parameters with regard to high efficiencies.

Electrolyzer & Fuel Cell Technology

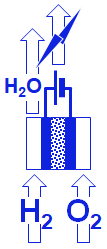

To produce and utilize hydrogen two components are of high importance. Firstly the electrolyzer which uses hydrogen containing matter like water (H2O) and separates the hydrogen from the oxygen with electrical power. The inverse process is utilized by the fuel cell, which generates electrical power with the reaction of hydrogen and oxygen.

Both components can be integrated into the in house design tools of B&B-AGEMA for innovative cycle design and preliminary dimensioning. Further detailed calculations are done with Simcenter STAR-CCM+ fully 3 dimensional including the chemical reaction, aerodynamics and heat transfer.

Hydrogen Infrastructure

To supply every component with the needed liquid or gaseous hydrogen, pipes and valves are necessary for small scale infrastructure in vehicles and for big scale structures in power plants. The infrastructure needs to operate on a long time scale and are exposed to corrosion and contamination. Especially hydrogen, due to its small atomic size, disperses into the materials and weakens them. By participating in research projects of the Forschungsvereinigung Verbrennungskraftmaschinen e.V. (FVV), B&B-AGEMA is actively working on solutions for better materials to use in the hydrogen infrastructure.