Combustion Technology

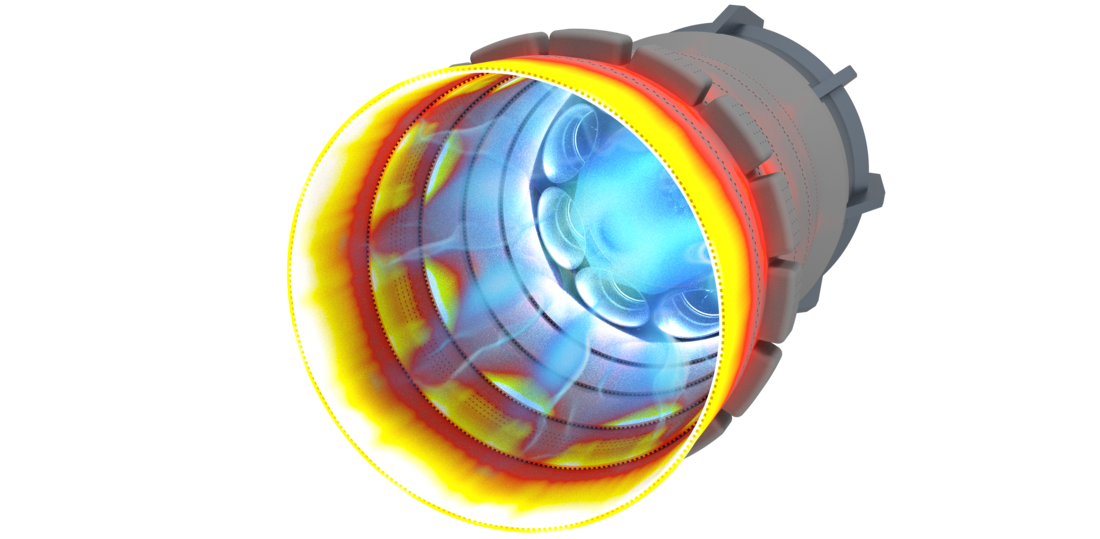

B&B-AGEMA has long-term experience in designing DLN combustion systems for gas turbines, from small scale jet turbines over turbofan engines up to stationary industrial and heavy-duty gas turbines. The company provides multidisciplinary services that cover the entire combustor development process:

- Feasibility, concept and detail designs (incl. manufacturing drawings)

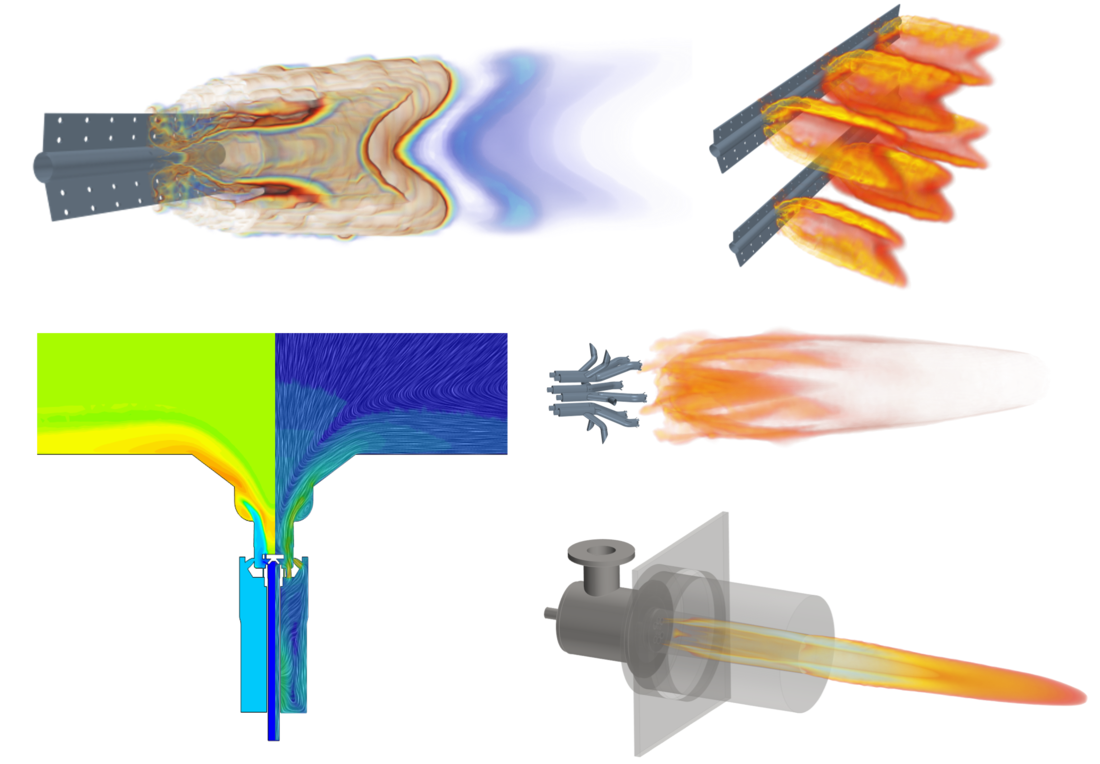

- Flow and reaction Simulations including Cooling concepts

- 0D / 1D Network & Chemical Reactor Modelling

- 3D Computational Fluid Dynamics (CFD) based on RANS and LES (see Combustion Simulation)

- Structural Integrity and failure analysis

- Prediction/Analysis of thermoacoustic oscillations („humming“; in-house tool CSC)

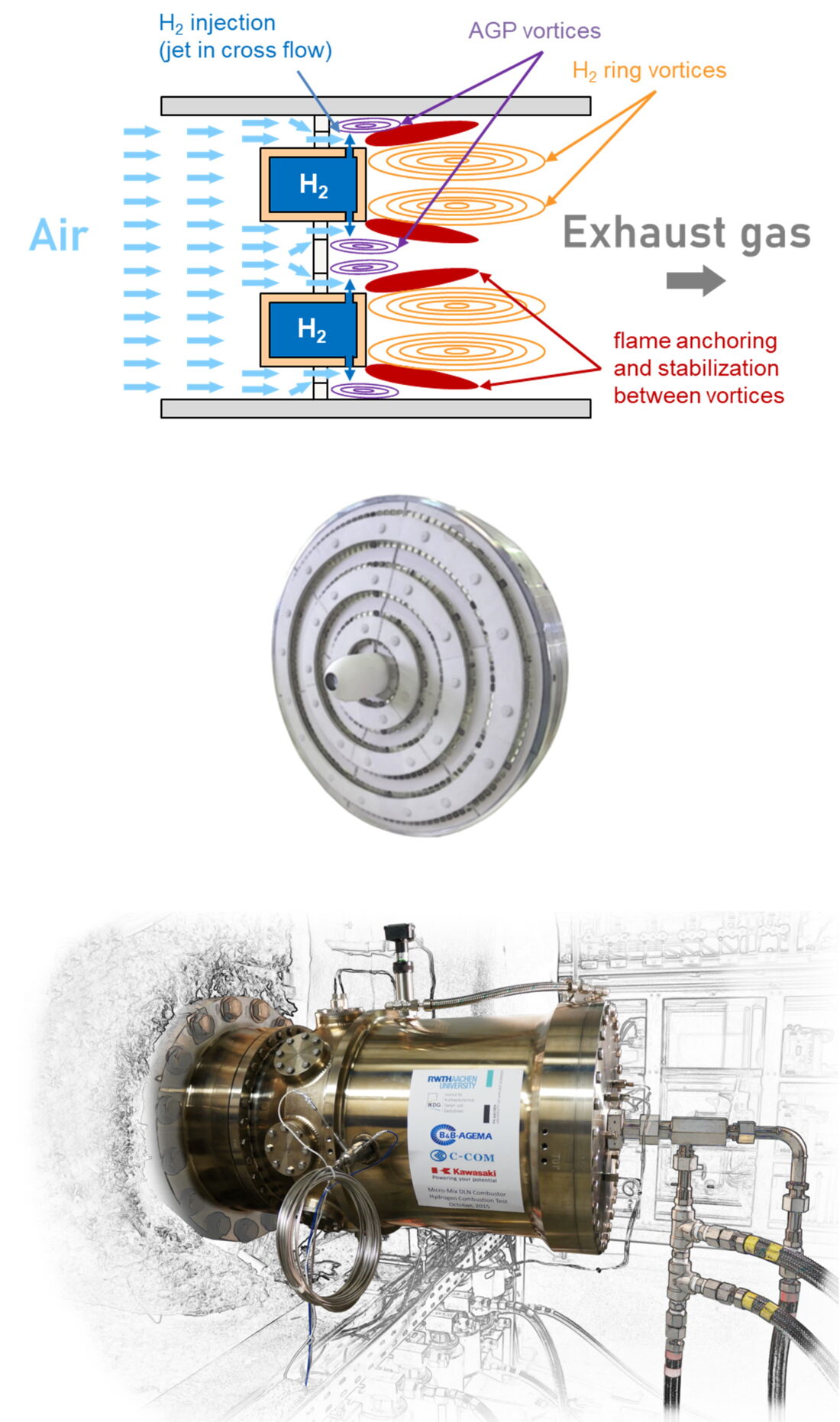

In a collaborative work B&B-AGEMA has developed the MicroMix combustion technology based on a flame miniaturization approach, which allows 100% Hydrogen to be burned safely and with low NOx emissions.

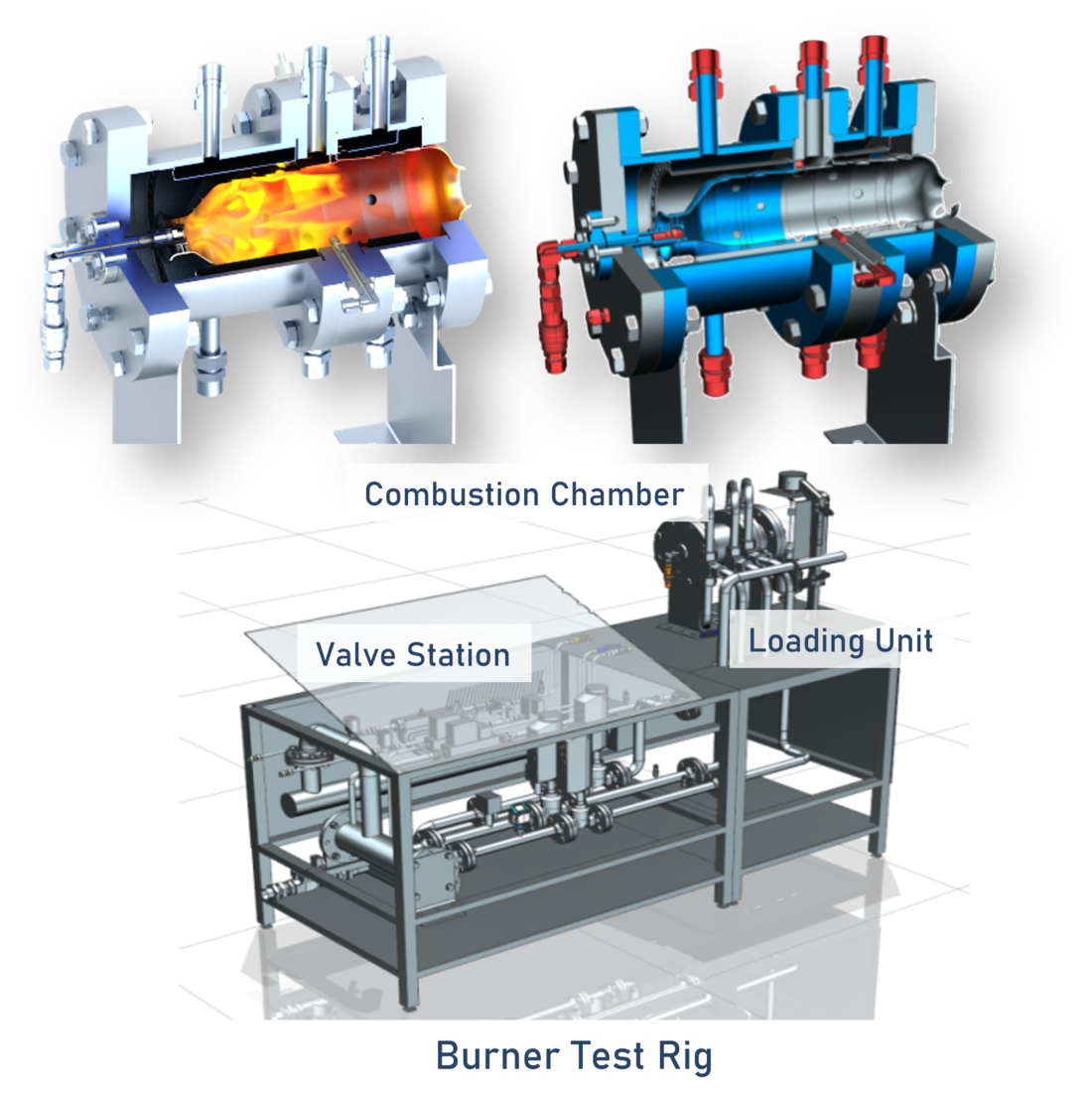

Besides gas turbine combustors B&B-AGEMA is also well experienced in the development of new burners for furnace (e.g. heat treatment) or plant applications (e.g. duct burner) as well as upgrading existing systems in terms of emissions, efficiency or fuel versatility (e.g. upgrade from pure natural gas operation to arbitrary natural gas hydrogen mixtures or pure hydrogen combustion).

In addition, B&B-AGEMA is capable of designing entire high temperature tests beds (Outlet-Temperature <1700°C, Outlet-Mach-Number <0.8) for special applications such as the investigation of thermal barrier coated (TBC) specimens in high velocity jets.

Numerical analyses can be supported by experimental investigations, which can be conducted in collaboration with our partners at RWTH Aachen University. On the gas turbine combustor test rig real operating conditions can be established with an air supply pressure up to 30 bar and air inlet temperature up to 550 °C. B&B-AGEMA has developed air-cooled borescopes for visual and infrared observations inside the combustors.