Gas Turbine

Since its foundation in 1995, the B&B-AGEMA has been included continuously in the new design, upgrade design and design verification of numerous well-known international OEMs of gas turbines in a huge range of power application (2 kW to 300 MW). Beside its core engineering skills, there are the tremendous experiences of the senior experts of B&B-AGEMA, which have been in leading and fully responsible positions in their companies for gas turbine design.

The company develops upgrade concepts for increased GT power output and efficiency as well as increased life time. Potentials of gas turbines are quantified in technical feasibility studies. Modern technologies, e.g. advanced film cooling technology, are developed and provided by B&B-AGEMA. Optimization of axial compressors with respect to mass flow, efficiency and operation range is performed by the B&B-AGEMA with its own software ACF2D.

B&B-AGEMA has long-term experiences in designing DLN combustors for gas turbines, which includes the special development of the MicroMix technology for 100vol% combustion of Hydrogen.

Hot gas path components require not only efficient cooling but also sustainable design with respect to the thermal fatigue topic.

B&B-AGEMA offers its expert know-how for design and development, upgrade, reverse engineering, and failure analyses of hot gas path components.

Cooled Axial Gas Turbines

Engineering Services for Cooled Axial Turbines:

- Aerodynamic Design 2D, 3D

- Cooling Design 3D: new design, upgrade & reverse engineering

- SAS Flow Path Design & Review

- Steady state and transient structural analyses

- Life time analyses

- Automated optimization work flow for design improvements

- Upgrade, Improvement and New design Development

Examples

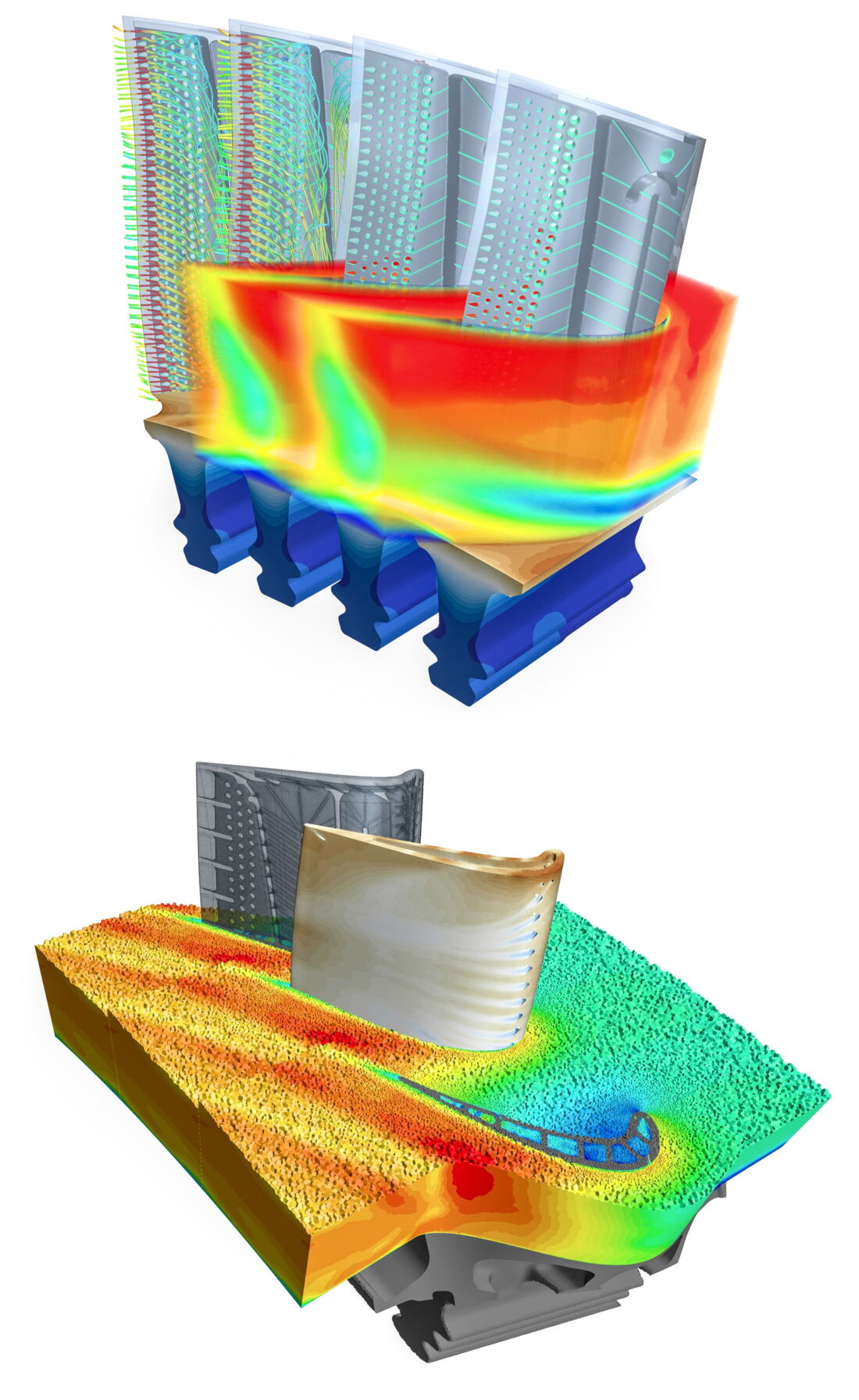

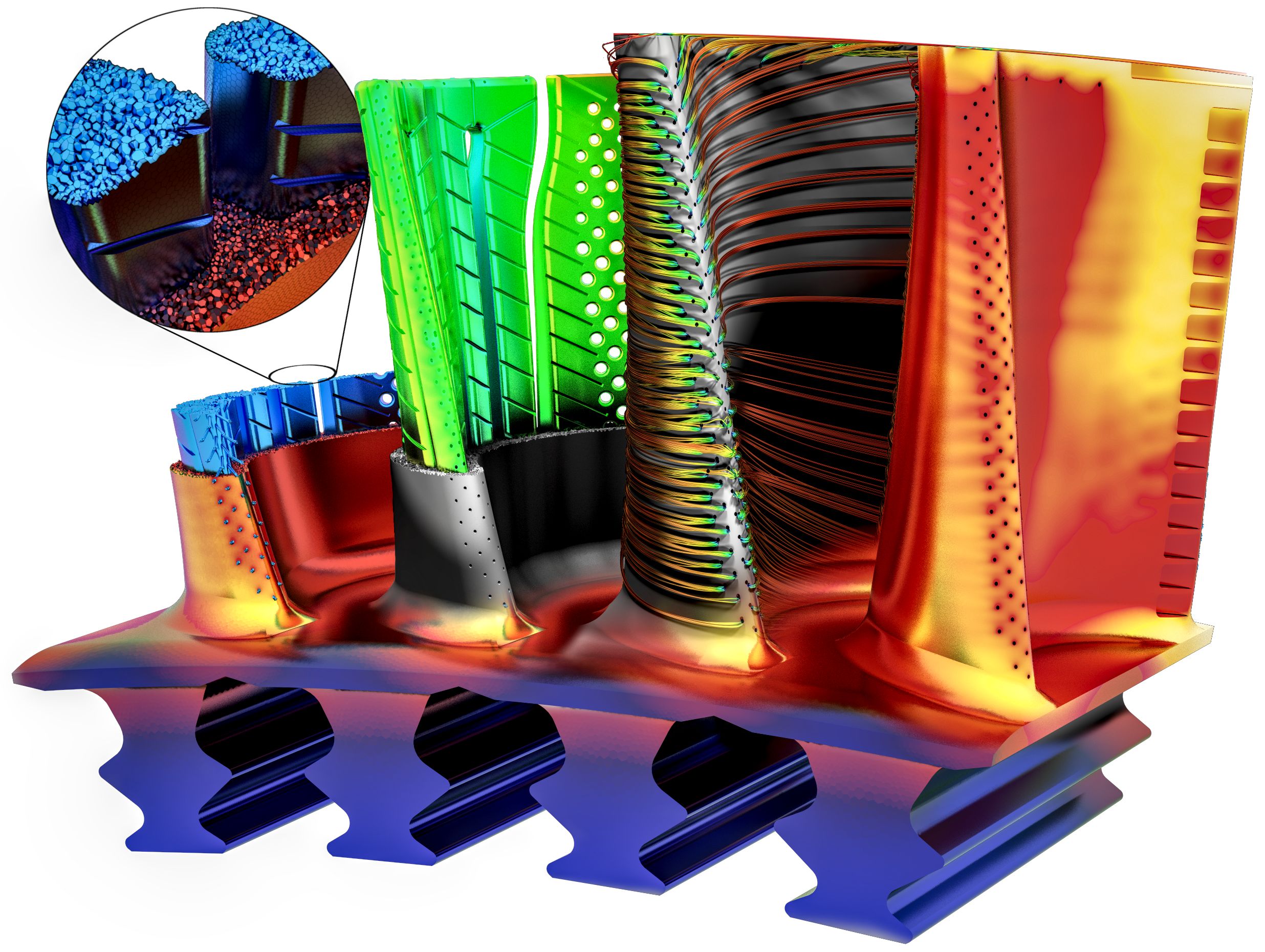

CHT-based Design of Modern Gas Turbine Cooling Configurations

- Development of advanced film cooling technologies for gas turbine first stage blade

- CHT-Simulation of blade body, main flow and cooling flow

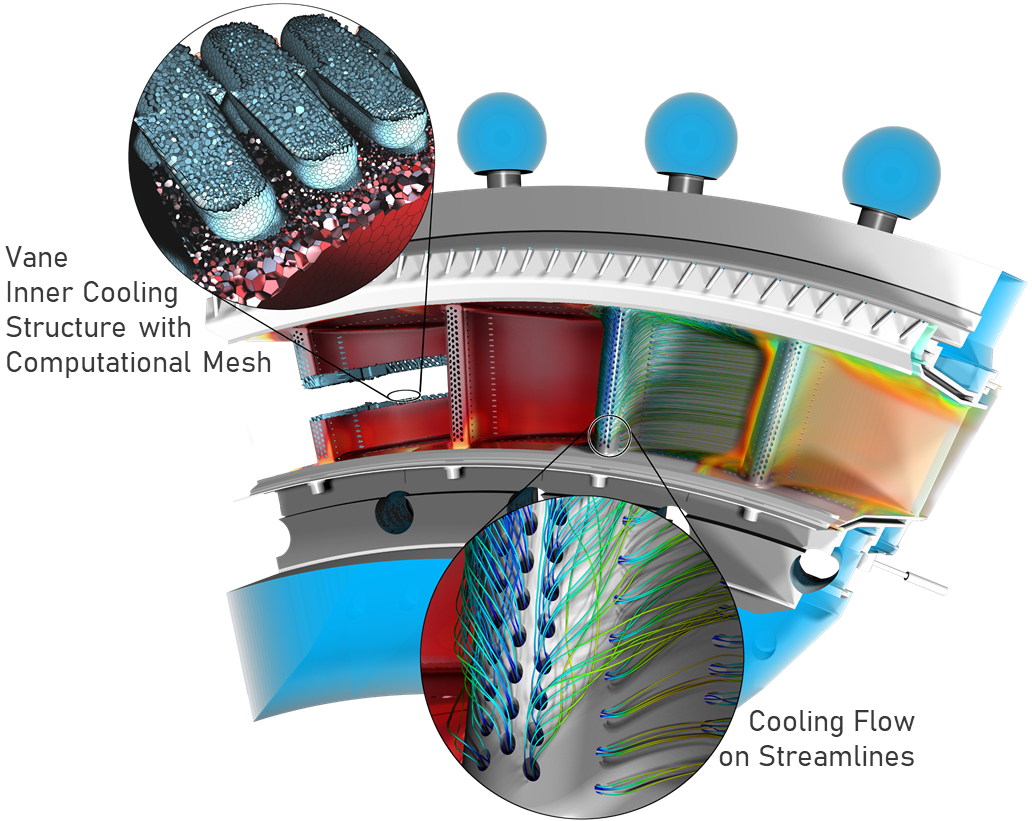

Experimentally verified CHT-simulation of First Stage Gas Turbine Vane with Advanced Cooling Technology

- Development of advanced film cooling technologies for gas turbine first stage vane

- Experimental validation of CHT-results by gas turbine OEM