Research Project „SAWES“

Advanced SAW-sensor technology for sustainable energy systems including wireless transponder and communication technology

In cooperation with partners in research and industry the SAWES project aims to develop a mobile, wireless and heat-resistant temperature sensor system based on the surface acoustic wave principle (SAW). The project is funded by the Federal Ministry for Economic Affairs and Climate Action within the “6th Energy Research Program of the Federal Government”.

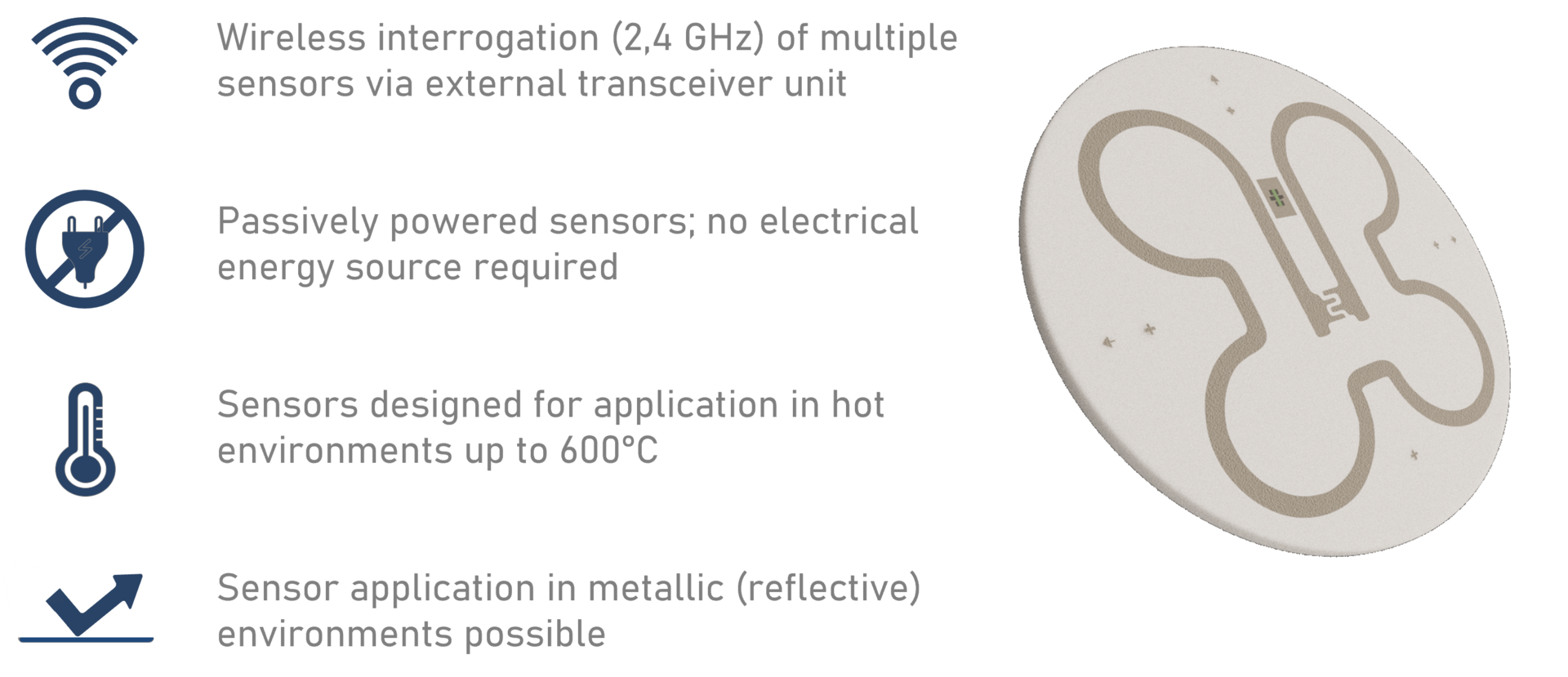

Key features:

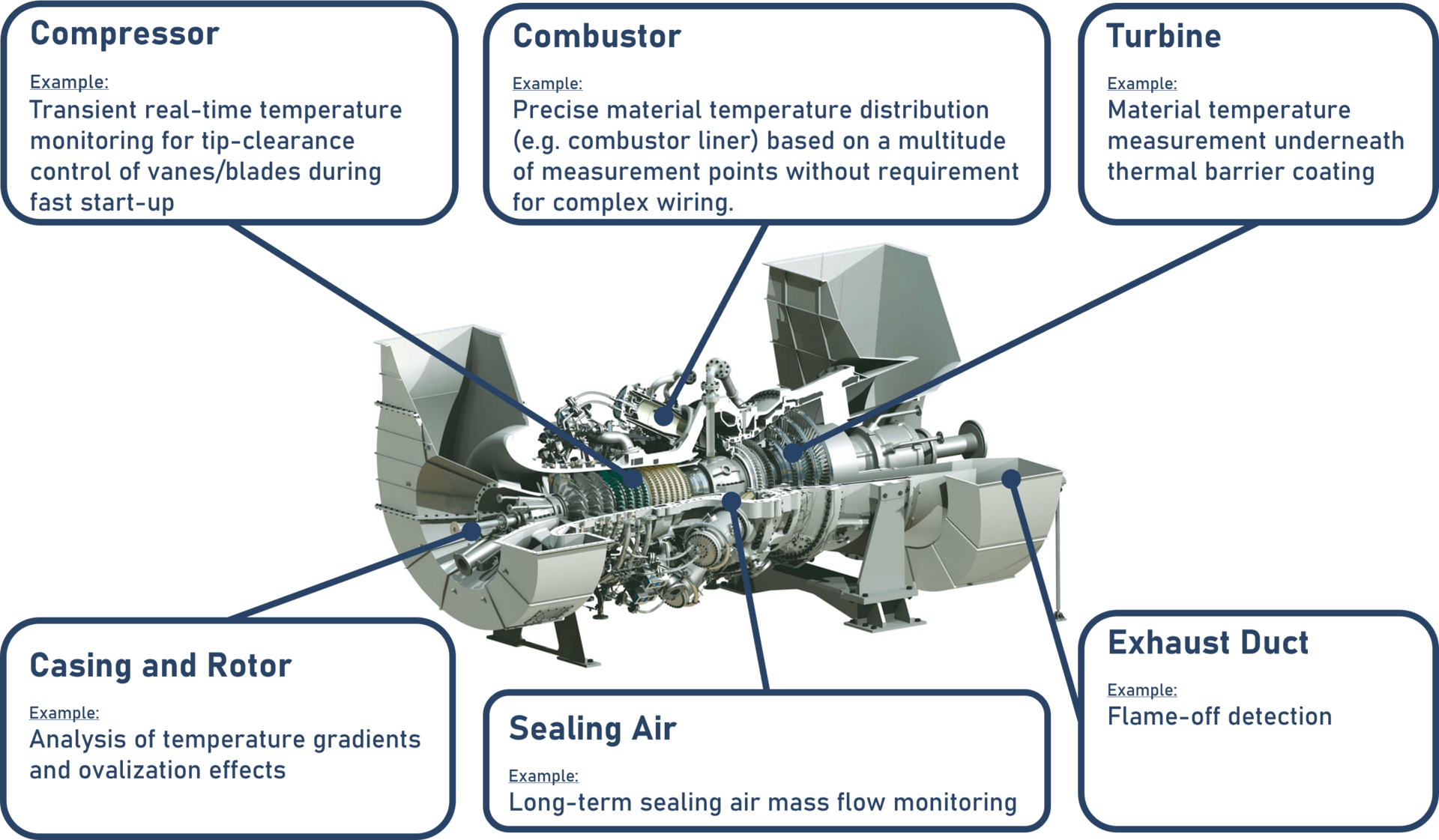

Compared to conventional temperature measurement systems the wireless data transmission and its passive power capability allows the SAW sensors to be applied within concealed areas that are difficult to access or moving components. Especially in turbomachinery applications, such as gas turbines or steam turbines, these features in combination with its heat resistance up to 600°C provide unprecedented opportunities in temperature monitoring.

Applications examples for an industrial gas turbine:

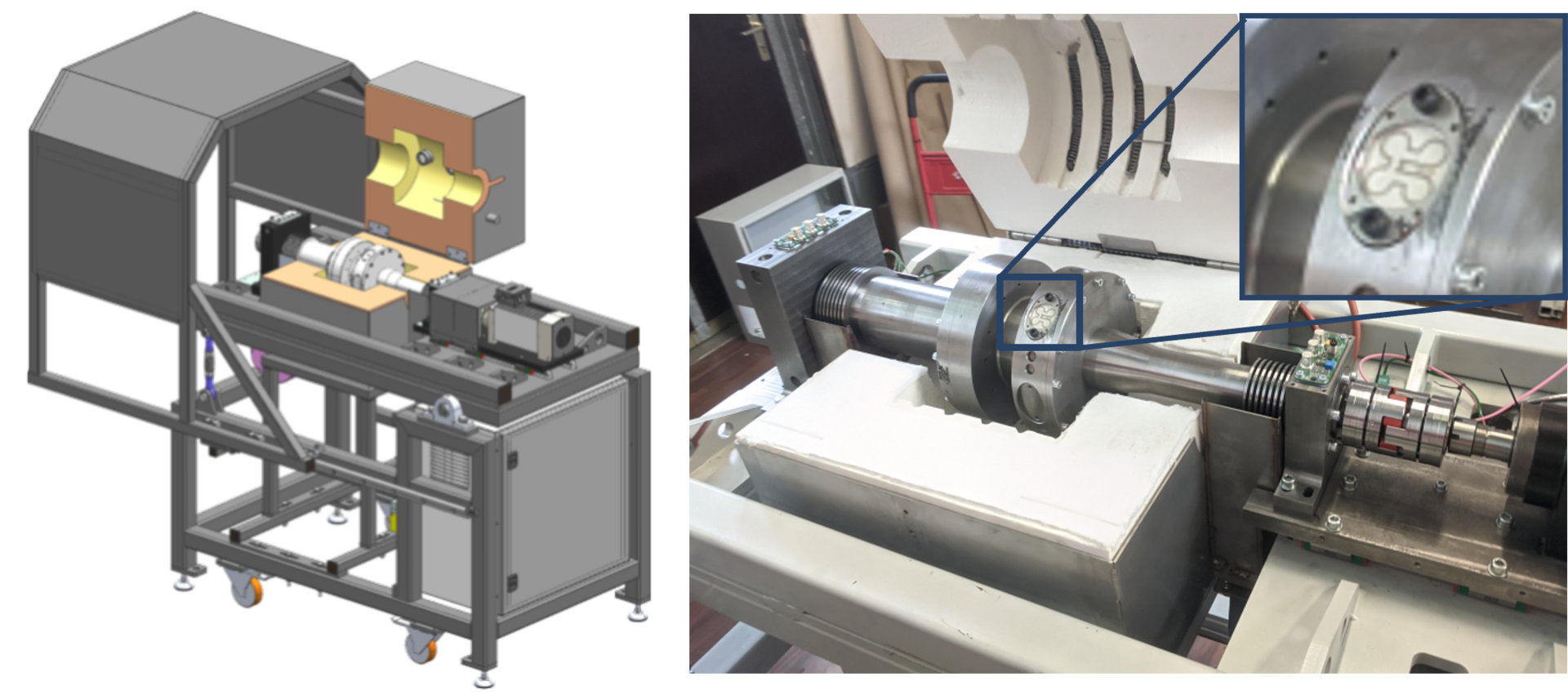

B&B-AGEMA’s responsibility within the SAWES project is the development of a test bench and the execution prototype sensor tests. The test bench is designed in such way that the SAW sensor can experience environmental conditions comaparable to those in industrial gas turbine applications in terms of thermal load and centrifugal force. The test stand is designed to create high temperature environments up to 600°C and deliver rotational speeds up to 10000 rpm. Beyond that the test stand allows analysing the sensor performance in reflective (metallic) environments with a variety of different sensor mounting positions.

Project partners:

Research Project „3DOxOx-Turbine“

Increasing efficiency and sustainability of stationary gas turbines by application of 3D-braided oxide-oxide ceramic matrix composites

The 3DOxOxTurbine research project is aimed at the production of 3D-braided, oxide-oxide (fibres and matrix made of aluminium oxide) ceramic matrix composite (CMC) components for hot-gas sections of stationary gas turbines. The project is funded by the Federal Ministry for Economic Affairs and Climate Action within the “7th Energy Research Program of the Federal Government”. 3DOxOxTurbine combines material and process development to create innovative high-temperature components by developing a die-castable slurry for the impregnation of 3D-braided ceramic fibre semi-finished products and then developing and testing a die-casting process for the automated production of corresponding fibre composite ceramics.

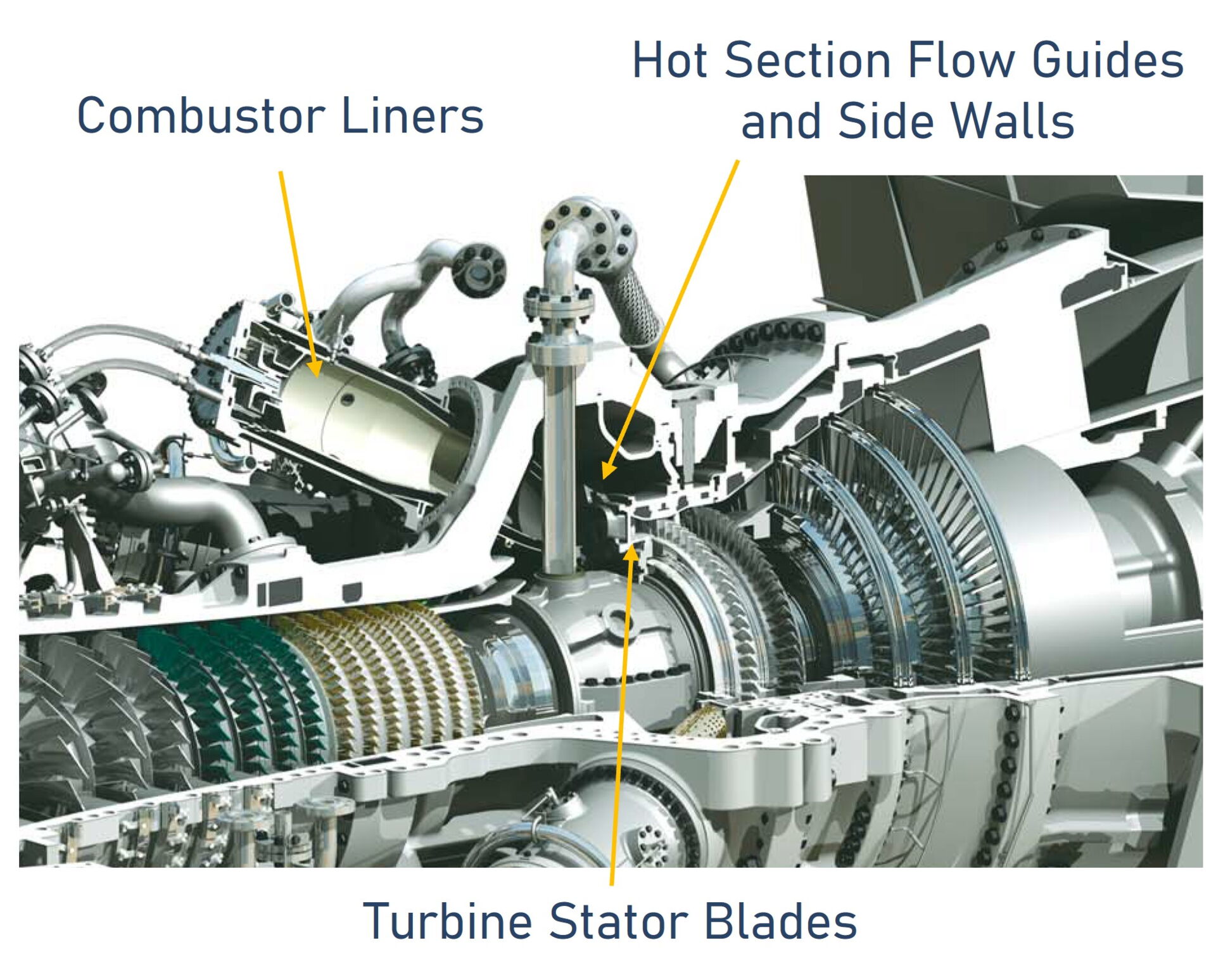

Use cases of CMCs in an industrial gas turbine:

CMCs offer the potential for efficiency improvement of stationary gas turbines and aero-engines. Compared to nickel-based superalloys, CMCs possess a higher temperature resistance, thus CMCs are particularly suitable for use in the hot gas section to reduce cooling air and increase turbine inlet temperature. Generally, the CMCs used in gas turbines today are based on silicon carbide fibres and matrices. Silicon carbide is prone to corrosion caused by water vapor in the combustion gas and needs to be protected by a barrier coating. A CMC made of aluminium oxide fibres and matrix possesses a high corrosion resistance, hence offering the potential to greatly increase service life of the components.

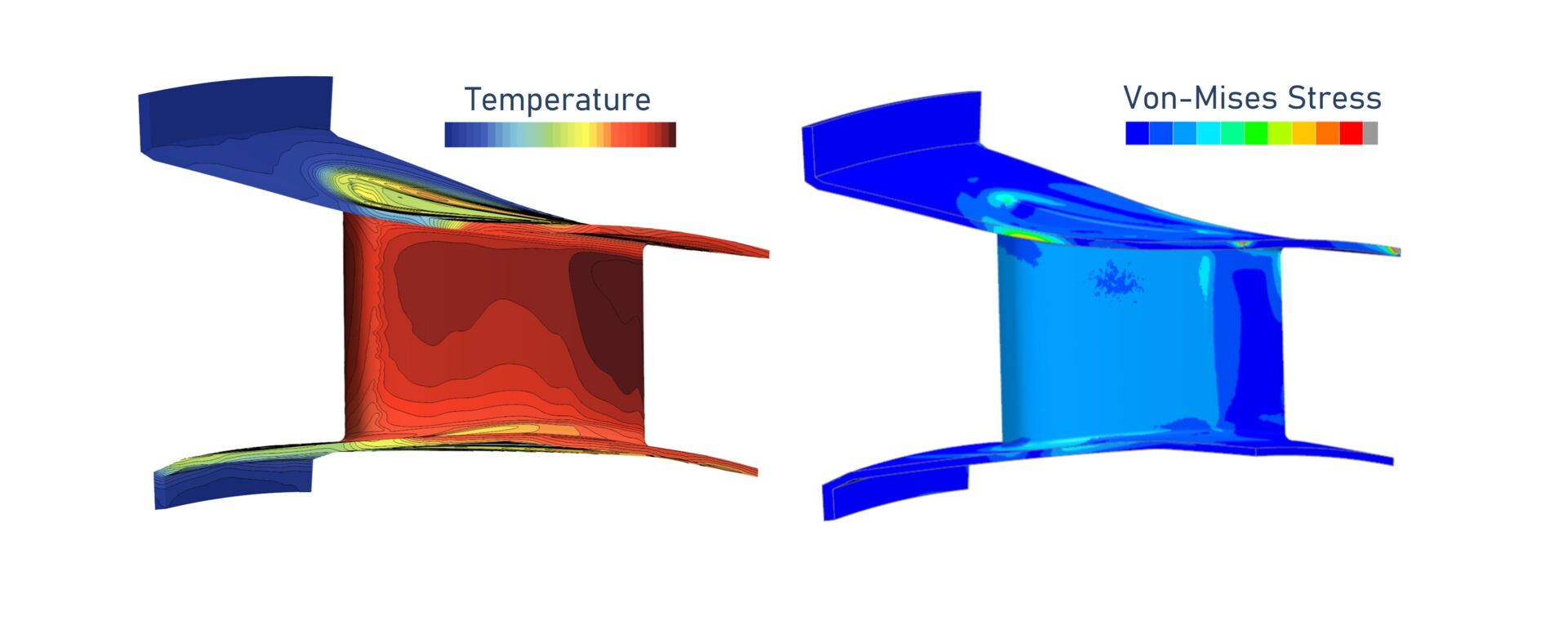

CHT and FEM simulation results of the CMC vane:

B&B AGEMA’s responsibility within the 3DOxOx Project is to numerically assess the potential a first stage vane made of the newly developed material with respect to thermodynamic efficiency and output power. This includes the structural design of the vane as well as a concept for mounting it to withstand the thermal and pressure loads present. The FEA will be based on the material properties derived from experimental test results of the fabricated CMC material.

Project partners:

Research Project “FeAl-GuD”

Process Development for the Fabrication of FeAl-Components for Combined Cycle Power Plants; Sub-Project: Material-related Component Design

Within the scope of the collaborative research project “FeAl-GuD”, which is funded by the Federal Ministry for Economic Affairs and Energy (BMWi), an intermetallic phase of iron and aluminium (FeAl) should be made available for power plant technology. Iron aluminides besides titanium aluminides belong to the most important intermetallic materials with high application potential as high-temperature materials.

B&B-AGEMA is focused on the aerodynamic and structural design of turbine bladings made of iron aluminides.

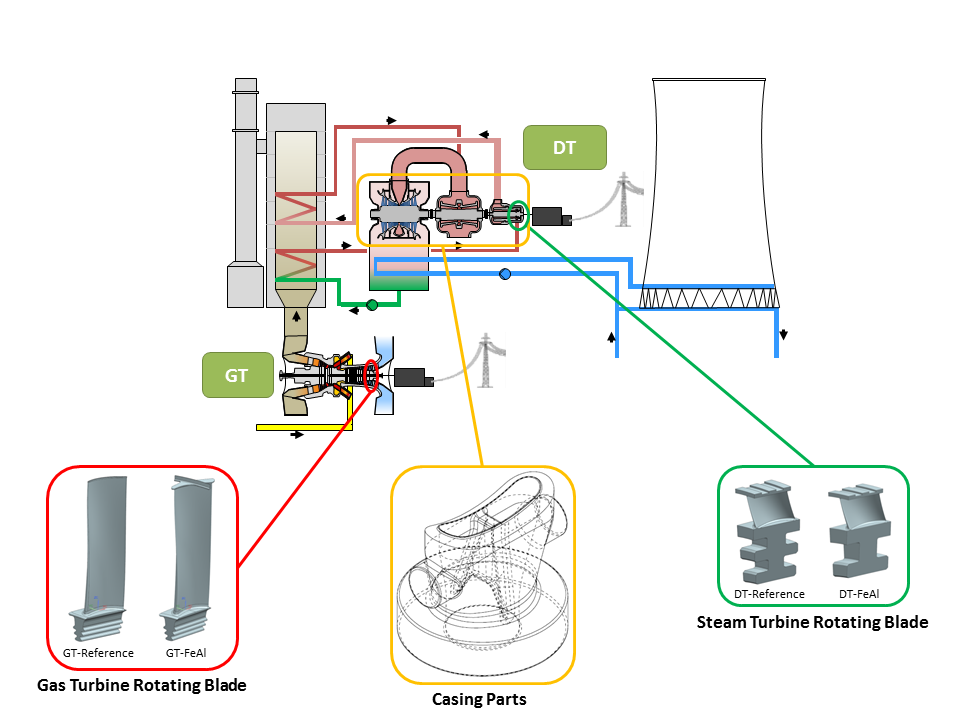

Application-oriented parts of a Combined Cycle Power Plant (CCPP):

Project details:

Combined cycle power plants (CCPP) optimally suite the task of grid stabilisation in terms of the electricity supply as part of the planned expansion of the renewable energies. CCPPs are characterised by short start-up and shutdown times, fast load changes and a comparatively high efficiency.

The last gas turbine stages usually are manufactured from nickel-base alloys and the first stages of high and intermediate pressure steam turbines mainly are made of high-alloyed heat-resistant steels. The application of an intermetallic phase of iron and aluminium (FeAl) yields the possibility for closing the gap in terms of the operating temperature among heat-resistant steels (operating temperature up to approx. 620 °C) and nickel-base alloys (operating temperature from approx. 700 °C). This enables an enhanced thermodynamic process control in CCPPs by increasing the gas turbine outlet temperature and the corresponding live steam temperature of the bottoming cycle. Hereby, the thermal process efficiency can be further improved whilst achieving a target quantity of 65 %.

Iron Aluminides offer a series of positive characteristics:

- high heat resistance in the range of 600 – 700 °C

- excellent corrosion and erosion resistance

- approx. 12 – 18 % lower density as steel, approx. 16 – 20 % lower density as Nickel-base alloys

- low material costs

- simple manufacturability

- long-term availability, since sparsely / no use of strategic elements (rare earths)

- completely recyclable

Lower density and improved material properties of FeAl enable shortened start-up and shutdown times of gas and steam turbines in contrast to the established materials as used in turbomachinery. The operational flexibility of CCPPs should be improved based on lowered moving masses by usage of FeAl.

Another project objective of B&B-AGEMA is the increase of aerodynamic turbine efficiency as a result of further development of flow-optimised blading geometry with reduced gap and secondary flow losses for outlet blading of the gas turbine and inlet blading of the steam turbine in consideration of the service possibilities of the new material.

After casting iron aluminides develop a coarse grain structure during solidification, which results in a low ductility and an increased susceptibility to cracking. On this account the casting process for the FeAl intermetallic compound should be improved by insertion of nucleation agents in the melt and a fine grain structure is expected. This will reduce the susceptibility to cracking and increase the room temperature ductility. Finally the mechanical behavior of the newly, grain refined FeAl material will be analysed and a database with the relevant material properties of low and high cycle fatigue (LCF / HCF), thermomechanical fatigue (TMF) and creep and oxidation properties will be established.

Project partners:

Research Project “HyFly”

Hybrid propulsion system for short-range aircraft

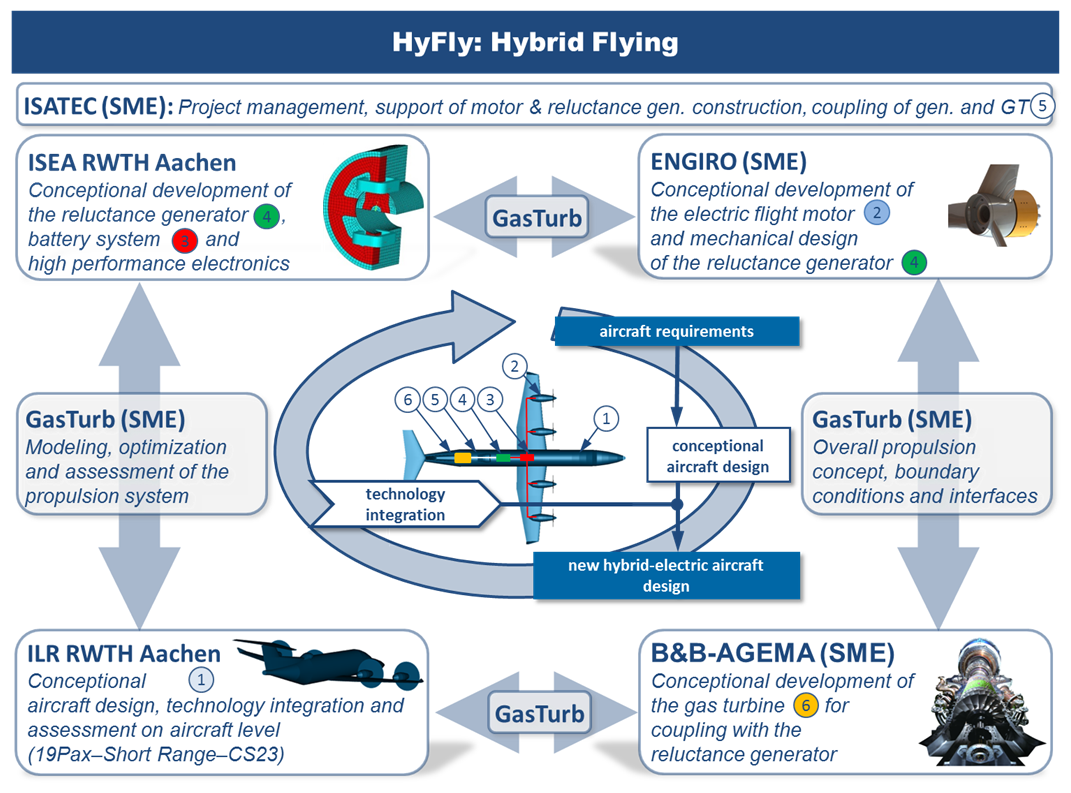

The overall goal of the HyFly project is the conceptual development of a hybrid electric propulsion system for the integration into a regional aircraft. It is intended to significantly contribute to the objective of reducing emissions with respect to pollutants and noise in aviation as defined in the European aviation vision “Flightpath 2050”.

This should be achieved by using hybrid drive architecture. The thrust is provided by electric motors. During the relatively short starting phase of the aircraft, which is most demanding for the power system, the engines are assisted by a battery. During cruise, the power is supplied by a reluctance generator, driven by a special gas turbine.

B&B-AGEMA focuses on the conceptual design of the gas turbine intended to drive the reluctance generator as well as the development of software for analysis of the operation and prediction of the long-term behavior of the GT.

Research concept:

Project details:

Due to the scalability of electric motors without internal loss in efficiency, it is possible to design new aircraft configurations with small span-spread, electrically driven propellers. This allows more efficient wing designs. The drive system to be developed within the present project will feature distributed purely electric drives with a bivalent power supply; consisting of a battery pack and a gas turbine with a directly coupled reluctance generator. This propulsion concept envisages that the high power required during the relatively short starting phase of the hybrid aircraft is provided by an on-board battery, which can be charged on the ground with electric energy obtained from renewable sources. During cruise, the aircraft's propulsion system is powered solely by an on-board turbine generator system. Accordingly, the objective of reducing emissions is achieved in two ways: On the one hand, the portion of energy to be extracted from fossil fuels is reduced by the amount that can be provided via renewable electricity; on the other hand, an eminently high efficiency can be reached for the gas turbine, since cyclic loading is not required. The operation of the GT at an optimized, very constant base load point allows the reduction of the fuel consumption and emissions.

One focus of the planned project is on the conceptual development of an in-flight power unit consisting of a high-performance reluctance generator and a gas turbine. It is characterized by the first time use of a switched reluctance machine for power generation for aircraft application. This type of generator operates very efficiently – especially at high rotational speeds – which is ideal for coupling to a gas turbine of the required power class. The battery-electric system supports the take-off phase and compensates quick load adjustment requirements. This reduces the rated output of the gas turbine compared to conventional drives and allows operation of the GT a constant turbine inlet temperatures and rotation speed. Extreme operating points and high mechanical and thermal stresses can be avoided. Thus, maintenance intervals can be extended and the overall life-time costs of the GT, reduced. The generated power is delivered to e-aircraft engines, whose predevelopment according to the requirements of the overall system analysis is also part of the project. With the system components to be examined, new aircraft and propulsion concepts can be realized.

The parallel integration of the models derived from the development of the new propulsion system components into the MICADO aircraft preliminary design environment, makes it possible on the one hand to design aircraft concepts with this propulsion system and to evaluate their operating costs, performance and eco-efficiency compared to existing reference aircraft. In the project HyFly a Dornier Do228-212 is examined. As a result, it should also be possible to prove the development success and the potential of hybrid-electric powered regional aircraft.

Project partners:

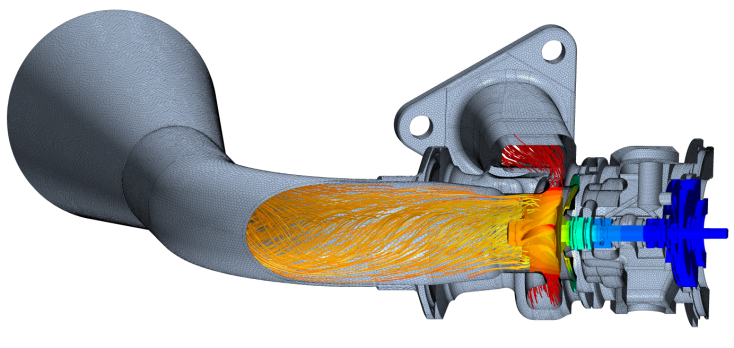

Research Project “PERMIT”

PERformance enhancement of MIcro Turbine based CHP systems

Within the scope of the collaborative research project “FeAl-GuD”, which is funded by the Federal Ministry for Economic Affairs and Energy (BMWi), an intermetallic phase of iron and aluminium (FeAl) should be made available for power plant technology. Iron aluminides besides titanium aluminides belong to the most important intermetallic materials with high application potential as high-temperature materials.

B&B-AGEMA is focused on the aerodynamic and structural design of turbine bladings made of iron aluminides.

Acknowledgement: